R2000 Bearings Selection

Basic Bearing Load Ratings

|

Shaft Size |

Dynamic Capacity | Static Capacity |

|---|---|---|

| 1 7/16

1 1/2 |

16,600 | 18,300 |

|

1 11/16

|

17,300 |

19,800 |

| 1 15/16

2 |

19,000 | 22,500 |

|

2 3/16 |

22,400 |

26,500 |

| 2 7/16

2 1/2 |

33,300 | 41,100 |

|

2 11/16

|

35,500 |

46,800 |

| 3 3/16

3 7/16 3 1/2 |

56,900 | 76,400 |

|

3 15/16

|

69,900 |

93,300 |

| 4 7/16

4 1/2 |

91,700 | 126,000 |

| 4 15/16

5 |

123,000 |

180,000 |

Royersford R2000 Spherical Roller Bearings have the capacity to carry substantial radial loads, thrust loads and combined radial/thrust loads. The maximum recommended load which can be applied is limited by the various components of the system, such as bearing, housing, shaft, shaft attachment, speed and life requirements as listed in this catalog.

Select a bearing from the R2000 Selection Chart having a radial load rating at the operating speed equal to or greater than the calculated "Equivalent Radial Load" for a desired L10 Life. This simple method is all that is required for a majority of general applications and provides for occasional average shock loads.

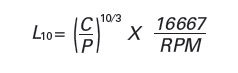

L10 Hours of Life – is the life that may be expected from at least 90% of a given group of bearings operating under identical conditions. To determine L10 hours for loads & RPM's not listed, use the following equation:

|

Where:

L 10 = Life hours C = Dynamic Capacity (from table 1) P = Equivalent Radial Load |

If the load on a double row spherical bearing is only in the radial direction (no axial load), the Equivalent Radial Load (P) is equal to the actual radial load. In situations where the bearing load consists of radial and axial (thrust) loads, the total load must be converted into an Equivalent Radial Load by the following equation:

|

P = XFR + YFA |

Where:

F A = Axial (thrust) Load F R = Radial Load X = Radial Load Factor from table 1 Y = Thrust Load Factor from table 1 |

To find the X and Y values, first calculate FA/FR and compare to the value of e in Table 1. Using the appropriate values for X and Y, substitute all known values into the Equivalent Radial Load equation. The result can then be used to determine the L10 life or compared to the radial load ratings in Table 2. If P is less than FR use P=FR If you have only axial (thrust) load, the equivalent radial load P = YFA where Y is taken from the column for values >e.

The magnitude and direction of both radial and thrust loads must be taken into account when selecting a housing. When pillow blocks are utilized, heavy loads should be directed thru the base. Where a load pulls the housing away from the mounting base, both the hold-down bolts and housing must be of adequate strength. Auxiliary load carrying devices (such as shear bars) are advisable for side or end loading of pillow blocks and radial loads for flanged units.

|

Shaft Tolerances |

|

|---|---|

|

Shaft Size |

Tolerance |

| UP TO 1 15/16" | +.0000 -.0005" |

| 2" TO 5" | +.0000 -.0010" |

The effectiveness of the shaft attachment to carry a thrust load depends on proper tightening of the set screws, shaft tolerance and shaft deflections. It is advisable to use auxiliary thrust carrying devices (shaft shoulder, thrust collar, snap ring, etc.) to locate the bearing under heavier thrust loads or where extreme reliability is desired (see Table 3 for set screw information).

The shaft tolerances recommended below are adequate for normal radial and radial/thrust load applications. Where the applied radial load exceeds the Maximum Slip Fit Radial Load, a snug-to-light press fit of the shaft is required. Since the allowable load, especially at low RPM, is very large, the shaft should be checked to assure adequate shaft strength.

Table 1 – Radial/Thrust Factors

|

Shaft

|

e |

FA/FR ≤ e |

FA/FR > e |

Dynamic Capacity |

Static Capacity |

Seal Speed Limit RPM |

Maximum Allowable Slip Fit Radial Load (FR) LBS |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| X |

Y |

X |

Y |

Lbs |

Newtons |

Lbs | ||||

|

1 7/16 - 1 1/2 |

0.28 | 1.0 |

2.4 |

0.67 |

3.6 |

16600 |

73400 |

18300 |

2800 |

2000 |

|

1 11/16 - 1 3/4 |

0.26 | 1.0 |

2.6 |

0.67 |

3.9 |

17300 |

77000 |

19800 |

2650 |

2100 |

|

1 15/16 - 2 |

0.24 | 1.0 |

2.8 |

0.67 |

4.2 |

19000 |

84500 |

22500 |

2400 |

2300 |

|

2 3/16 |

0.24 | 1.0 |

2.8 |

0.67 |

4.2 |

22400 |

99600 |

26500 |

2150 |

2700 |

|

2 7/16 - 2 1/2 |

0.24 | 1.0 |

2.8 |

0.67 |

4.2 |

33300 |

148000 |

41100 |

1800 |

4000 |

|

2 11/16 - 3 |

0.22 | 1.0 |

3.0 |

0.67 |

4.6 |

35500 |

158000 |

46800 |

1600 |

4200 |

|

3 3/16 - 3 1/2 |

0.23 | 1.0 |

2.9 |

0.67 |

4.4 |

56900 |

253000 |

76400 |

1300 |

6800 |

|

3 11/16 - 4 |

0.24 | 1.0 |

2.8 |

0.67 |

4.2 |

69900 |

311000 |

93300 |

1200 |

8400 |

|

4 7/16 - 4 1/2 |

0.25 | 1.0 |

2.7 |

0.67 |

4.0 |

91700 |

408000 |

126000 |

1100 |

11000 |

|

4 15/16 - 5 |

0.26 | 1.0 |

2.6 |

0.67 |

3.9 |

123000 |

547000 |

180000 |

900 |

14800 |

Table 2 – Easy Selection Table

|

Shaft

|

L10 Life Hours |

Radial Load Ratings (Lbs.) at Various Revolutions per Minute | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 |

100 |

250 |

500 |

1000 |

1200 |

1500 |

1750 |

2000 |

2500 |

||

|

1 7/16 - 1 1/2 |

5000

10000 30000 50000 100000 |

7365

5980 4300 3690 3000 |

5980

|

4545

|

3690

|

3000

|

2835

|

2655

2155 1550 1330 1080 |

2535

|

2435

1975 1420 1220 990 |

2275

|

|

1 11/16 - 1 3/4 |

5000

10000 30000 50000 100000 |

7675

6235 4485 3845 3125 |

6235

5065 3640 3125 2535 |

4735

3845 2765 2370 1925 |

3845

3125 2245 1925 1565 |

3125

2535 1825 1565 1270 |

2955

2400 1725 1480 1200 |

2765

2245 1615 1385 1125 |

2640

2145 1540 1320 1075 |

2535

2060 1480 1270 1030 |

2370

|

|

1 15/16 - 2 |

5000

10000 30000 50000 100000 |

8430

6845 4925 4225 3430 |

6845

|

5200

4225 3035 2605 2115 |

4225

|

3430

2785 2005 1720 1395 |

3245

|

3035

2465 1775 1520 1235 |

2900

|

2785

2260 1625 1395 1135 |

----

|

|

2 3/16 |

5000

10000 30000 50000 100000 |

9940

8070 5805 4980 4045 |

8070

|

6130

4980 3580 3070 2495 |

4980

|

4045

3285 2360 2025 1645 |

3830

|

3580

2910 2090 1795 1455 |

3420

|

3285

2665 1920 1645 1335 |

----

|

|

2 7/16 - 2 1/2 |

5000

10000 30000 50000 100000 |

14775

12000 8630 7405 6015 |

12000

|

9115

7405 5325 4570 3710 |

7405

|

6015

4885 3510 3015 2445 |

5695

|

5325

4325 3110 2665 2165 |

5085

|

4885

3965 2850 2445 1985 |

----

|

|

2 11/16 - 3 |

5000

10000 30000 50000 100000 |

15750

12795 9200 7895 6410 |

12795

|

9720

7895 5675 4870 3955 |

7895

|

6410

5205 3745 3210 2610 |

6070

|

5675

4610 3315 2845 2310 |

5420

|

----

---- ---- ---- |

----

|

|

3 3/16 - 3 1/2 |

5000

10000 30000 50000 100000 |

25250

20510 14750 12655 10275 |

20510

|

15580

12655 9100 7805 6340 |

12655

|

10275

8345 6005 5150 4180 |

9730

|

----

---- ---- ---- |

----

|

----

---- ---- ---- |

----

|

|

3 11/16 - 4 |

5000

10000 30000 50000 100000 |

31020

25165 18120 15545 12625 |

25195

|

19140

15545 11180 9590 7790 |

15545

|

12625

10255 7375 6325 5140 |

11955

|

----

---- ---- ---- |

----

|

----

---- ---- ---- |

----

|

|

4 7/16 - 4 1/2 |

5000

10000 30000 50000 100000 |

40695

33050 23770 20395 16565 |

66050

|

25110

20395 14665 12585 10220 |

20395

|

16565

13455 9675 8300 6740 |

15680

|

----

---- ---- ---- |

----

|

----

---- ---- ---- |

----

|

|

4 15/16 - 5 |

5000

10000 30000 50000 100000 |

54585

44335 31885 27355 22220 |

44335

|

33680

27355 19675 16880 13710 |

27355

|

22220

18045 12980 11135 9045 |

----

|

----

---- ---- ---- |

----

|

----

---- ---- ---- |

----

|

Table 3 - Set Screw Information

|

Shaft Size |

Set Screw | Tightening Torque |

Permissible Axial Load |

|

|---|---|---|---|---|

|

Inches |

No. | Size |

In-Lbs |

Lbs |

|

1 7/16 - 2 3/16 |

2 | 3/8"-24 |

250 |

515 |

|

2 7/16 - 3 1/2 |

2 | 1/2"-20 |

620 |

900 |

|

3 11/16 - 4 |

2 | 5/8"-18 |

1325 |

1200 |

|

4 7/16 - 5 |

4 | 5/8"-18 |

1325 |

2400 |